苏州微流纳米生物技术有限公司

Recently, engineers from Suzhou Microfluidic Nanobiotechnology Co., Ltd. went to Sichuan University to install and train the NanoDeBEE45 -4 high-pressure microjet homogenizer.

Figure Installation and acceptance of NanoDeBEE 45-4 high-pressure microjet homogenizer at the School of Polymer Science and Engineering, Sichuan University

NanoDeBEE 45-4 high-pressure microjet homogenizer, the actual operating pressure range is 2,000- 45,000 PSI(3000Bar), the pressure is continuously adjustable through the knob, the sample processing flow rate is 70ml/min (4L/Hr), as small as the sample processing capacity can reach 12ml. It is divided into two parts: machine station and pump station. The pump station provides stable hydraulic driving force for the equipment. The machine station is the core component of control and homogenization. The core of the homogenizer uses unique nozzle injection and high shear in the emulsion chamber and the opposite injection of front and rear materials to efficiently carry out material nanoprocessing.

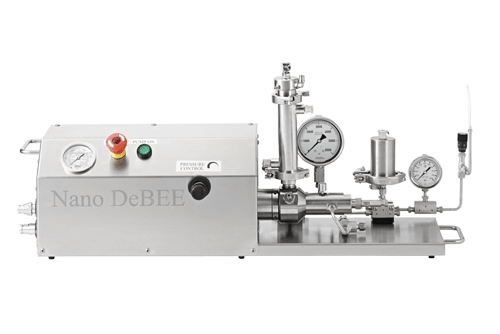

Nano DeBEE is a versatile product development device that includes highly flexible and easy-to-use methods for making novel emulsions, dispersions, liposomes and cell disruption. Nano DeBEE is sufficient to achieve unparalleled results in mixing, homogenization, particle size reduction in the laboratory, and is easy to operate and maintain.

The Nano DeBEE system has two separate subsystems, a work unit and a power unit, connected by two hydraulic hoses and cables.

Figure NanoDeBEE Work Cell

The work cell on the desktop contains a patented booster pump and work system. After adding material to the inlet container, the booster pump starts and then begins a slow cycle, first with the suction stroke drawing fluid into the pump, and then the power stroke pushing the material into the emulsification chamber (EC). The volume of pressurized material (available as high as 30,000 or 45,000 PSI) is less than 10 ml.

Strong shearing, cavitation, impact destruction, and mixing are carried out in the emulsion chamber to produce a completely mixed, smaller particle size, and homogeneous product. After exiting the emulsion chamber, the material may be cooled in an optional heat exchanger. An additional back pressure control can be added to regulate the pressure applied as material flows between the emulsion chamber and the outlet. The modular emulsion chamber, adjustable back pressure and cooling are key to Nano DeBEE's high flexibility and ease of use in making novel emulsions.

Figure NanoDeBEE Hydraulic Power Unit

Hydraulic power units provide power to Nano DeBEE. This unit is generally installed under the stage or in the work area. It includes a standard motor, hydraulic pump, solenoid valve, filter and heat exchanger. Hydraulic cylinders with pressurized oil entering the working unit from the hydraulic power unit push it back and forth. The volume of pressurized oil is only 0.5 liters.

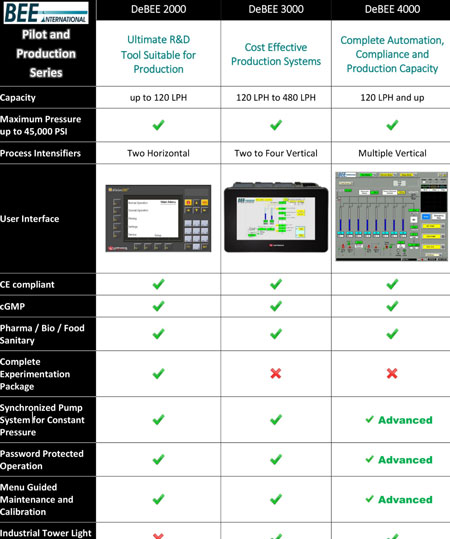

In the picture, the production-type BEE microjet high-pressure homogenizer was included

in the "Entity List" and encountered some troubles during the cooperation process. Through coordination and communication between Suzhou Microfluidic Nano and all parties, the final problem was successfully overcome. Sichuan University will also purchase another NanoGenizer next month.

Themicrojet high-pressure homogenizersupplied by Suzhou Microflow Nano can not only be used for complex injection preparations, dispersion, peeling and refinement of nanomaterials, preparation of cosmetics nanoemulsions, but also in many fields such as food macromolecular modification, fine preparation of beverages and dairy products. Can play an important role.

苏州微流纳米Vic