苏州微流纳米生物技术有限公司

Magnetic materials can be widely used in the information industry, automotive industry, power equipment, household appliances, petrochemicals, machinery manufacturing, aerospace, medical equipment and other fields. Nano-magnetic material dispersions can be used in the production and preparation processes of various electronic parts, magnetic heads, mechanical equipment parts, electronic testing instruments, audio-visual equipment, optical communication products, etc.

Recently, Suzhou Microflow Nanobiotech Co., Ltd. received dispersion samples of magnetic materials from customers and entrusted the company to prepare nanoemulsion samples. It requires that the target phase of the packaging material can be stably and uniformly distributed in the solvent phase, and the particle size of the target phase should not exceed 150nm. After screening and optimizing the treatment process by technicians of Suzhou Microflow Nanobiotech Co., Ltd., a uniform and stable magnetic material nanoemulsion with a particle size of 120nm was successfully prepared.

Samples and processing equipment:

Nanogenizer 30K microjet high-pressure homogenizer Suzhou Microfluid Nanobiotech Co., Ltd. supplies

high-speed shearing machines, customer-provided

samples provided by customers

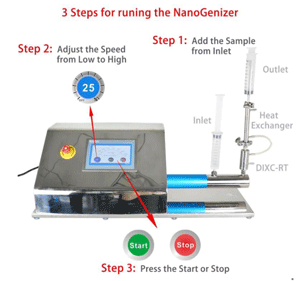

Figure Operation demonstration of Nanogenizer 30K microjet high-pressure homogenizer

Brief description of operating steps and results:

1.& nbsp;Genizer microjet high-pressure and low-pressure pre-disperse the sample once

2.& nbsp;Genizer Microjet High-pressure Homogenizer Y-shaped cavity + different pressures + different times of dispersion processing

3.& nbsp;Genizer Microjet High-pressure Homogenizer Z-shaped cavity + different pressures + different times of dispersion processing

After processing, the appearance

samples will be returned to the customer for property identification and particle size testing.

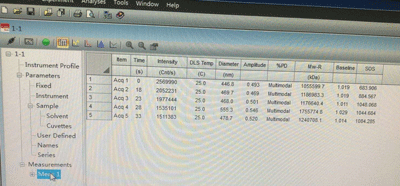

Control group particle size test results

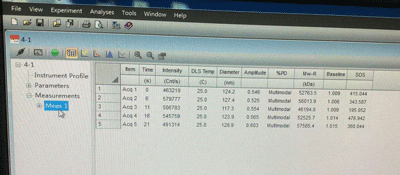

Experimental group particle size test results

苏州微流纳米Vic