苏州微流纳米生物技术有限公司

The high-pressure homogenizer can be used for the preparation of micro and nano materials: it is suitable for the preparation of nanoemulsions, liposomes, nanosuspensions, etc., cell disruption, particle reduction and other processes, generally through cavitation effect, high-frequency shearing, collision and other effects, achieve the micro-nano effect of materials.

Regarding the differences and respective characteristics between "microjet high-pressure homogenizer" and "homogenization valve high-pressure homogenizer", this article will briefly describe:

1. Homogenization core

Homogenization valve type high-pressure homogenizer:

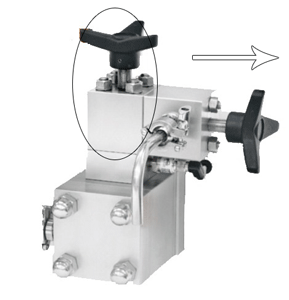

1) A first-and second-stage homogenization valve. The appearance structure of the homogenization valve homogenization unit is as shown in Figure 1 and the working principle of the homogenization valve is as shown in Figure 2;

2) The homogenization core material is generally hard metal, ceramics or Stellite alloy;

3) The homogenization channel is an annular gap, and the gap size between the valve cores is manually adjusted to control the homogenization pressure, as shown in Figure 1, the homogenization gap is adjusted through the hand wheel;

4) The design gap of the homogenization valve is large, and the upper pressure limit is relatively low. Wear of the homogenization core and the peeling of metal particles are easy to occur during high pressure or particle homogenization;

5) After clogging, it can be treated by adjusting the gap, but after the process is scaled up, it is not easy to fully reproduce the results and control of the small scale.

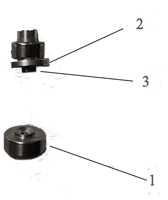

Figure 1 Exterior view of the homogenization unit of the homogenization valve (left) and anatomical view of the handwheel adjustment homogenization valve (right)(1-base 2-impact ring 3-valve seat)

Figure

Figure

2 Physical diagram of the core components of the homogenization valve and schematic diagram of the homogenization principle (1-base 2-impact ring 3-valve column 4-homogenized material)

Microjet high-pressure homogenizer:

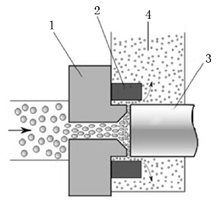

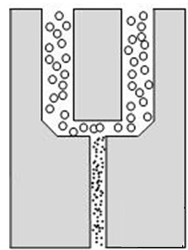

1) It is equipped with a Y-shaped counter-jet diamond interactive chamber, and the appearance structure and principle are as shown in Figure 3;

2) The core reaction parts are mostly made of diamond, and other materials in contact with the material are made of 316L stainless steel materials recognized by the FDA;

3) The material passes through holes of a hundred micron level to form 2 or more sonic jets, which collide with each other at the other end of the diamond interactive chamber, causing cavitation effects, high-frequency shearing effects, etc.;

4) The self-phase collision effect of the sonic jets is increased, making the homogenization more efficient, and at the same time greatly reducing the collision and wear of the material on the chamber and prolonging the service life of the chamber;

5) The interior of the chamber is a fixed structure, which can achieve efficient reproduction and amplification of the process by increasing the number of reaction channels of the same specification.

Figure 3 The interaction cavity and action principle of jet diamond

2. Pressure regulation

homogenization valve type high-pressure homogenizer: It often has a handwheel, through which the pressure is continuously adjusted manually. The upper pressure limit is generally lower than that of microjet high-pressure homogenizers of the same level.

Microjet high-pressure homogenizer: The homogenization pressure is continuously controlled through touch screen adjustment, and the upper pressure limit is relatively higher.

3. Power unit

homogenization valve type high-pressure homogenizer: The motor uses a crankshaft connecting rod to drive the plunger to reciprocate homogenization, with a high frequency (2-3 times/s), and the overall weight is heavier than that of a microjet high-pressure homogenizer of the same magnitude.

Microjet high-pressure homogenizer: Hydraulic drive or direct motor drive plunger reciprocates, low frequency (6-10s/time), and high pressure part of pressure pulse accounts for a large proportion.

4. Homogenization unit

Homogenization valve type high-pressure homogenizer: Homogenization unit is shown on the left of Figure 4. Large rectangular stainless steel modules are commonly used. The modules include material inlets and outlets, one-way valve interfaces, homogenization valve interfaces, pressure gauge interfaces, etc. The modules are of large mass, relatively cumbersome to assemble and disassemble, large residual volume in the pipeline, and small sample processing to relatively large volume values.

Microjet high-pressure homogenizer: The homogenization unit is shown on the right of Figure 4. It adopts the form of a pipeline interface directly connected to the high-pressure cylinder body. It has a small weight. It is attached to a cylindrical plunger through a one-way valve. The residual volume of the entire reaction channel can be less than 1ml, as small as the reaction volume is 5ml.

Figure 4 Homogenization unit of homogenization valve homogenizer (left) and homogenization unit of microjet high-pressure homogenizer (right)

5. Instrument cost

Homogenization valve type high-pressure homogenizer: The core component of homogenization is the homogenization valve. The application of highly hard metal or ceramic components makes the homogenization valve type high-pressure homogenizer have relatively lower cost and price.

Microjet high-pressure homogenizer: The homogenization core component is made of diamond. Compared with the homogenization valve type homogenization core, it has a more complex process and higher homogenization efficiency. This is also the use of microjet high-pressure homogenizer in some high value-added fields. One of the reasons why it is more preferred.

6. Better application areas

Homogenization valve high-pressure homogenizer: Due to its price and difficulty in clogging, it is suitable for general value-added homogenization fields such as biological cell disruption, high-viscosity chemical materials, dairy beverages, pigment inkjet, and particle crushing that does not require high purity. If the price of microjet high-pressure homogenizers is reduced, the advantages of homogenization valve high-pressure homogenizers will be reduced;

microjet high-pressure homogenizers: In the field of general nano homogenization and dispersion and the preparation of high value-added cosmetics, nano new materials, foods, graphene, pharmaceuticals (such as paclitaxel liposomes, alprostadil, propofol, etc.) nanoemulsions, liposomes, and nanosuspensions, have a higher homogenization effect and a lower demulsification rate than the homogenization valve type.

What common high-pressure homogenizer manufacturers are currently on the market?

1) Common homogenization valve high-pressure homogenizer brands (in no particular order):

APV、Avestin、GEA Niro、ATS、PHD (optional diamond interactive chamber type was also introduced in 2019), BEE (nozzle type), domestic high-pressure homogenizer, etc.

2) Common microjet high-pressure homogenizer brands:

Microfluidics、Genizer

| manager Wang Tel: 13020218906 Email: biotech@willnano.com Website: www.willnano.com Suzhou Microfluidic Nanobiotechnology Co., Ltd. |