苏州微流纳米生物技术有限公司

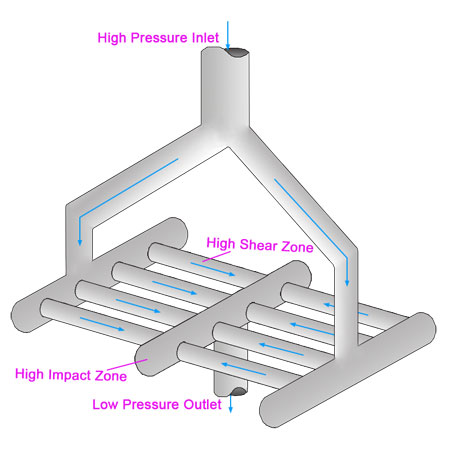

The microjet high-pressure homogenizer is a high-pressure homogenizer equipped with the second-generation microjet diamond interactive chamber. In the process of nanoprocessing materials by the microjet high-pressure homogenizer, it utilizes dynamic high-pressure microjet, high shear, high-energy collision (turbulent collision), cavity effect and other forces, and is suitable for liquid-liquid emulsification, liposome preparation, Nanodispersion, deagglomeration, particle size reduction, cell disruption and other processes of solid materials in liquids. These core high-energy reactions of the microjet high-pressure homogenizer all occur in a microjet diamond interaction chamber with a fixed internal shape (Z-type or Y-type) and a specific aperture.

Figure 1 Experimental microjet high-pressure homogenizer

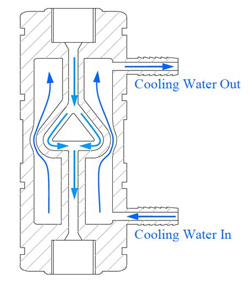

Figure 2 Equipment core: Microjet diamond interactive chamber

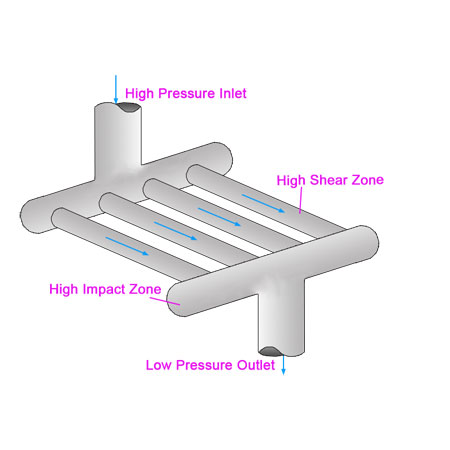

Microjet diamond interactive chamber:

Microjet diamond interactive chamber is the place where high-speed jets, high shear, high-energy collisions and other effects occur. The interior is a fixed Y or Z-type diamond microporous channel, with a pore size as small as 50um. The fixed geometry ensures consistent action effects (and completely repeatable particle size distribution).

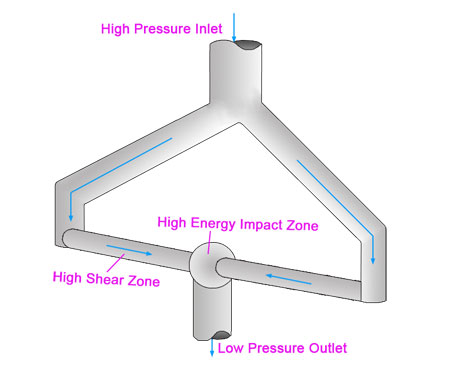

Figure 3 Single channel Y-type microjet diamond interactive cavity

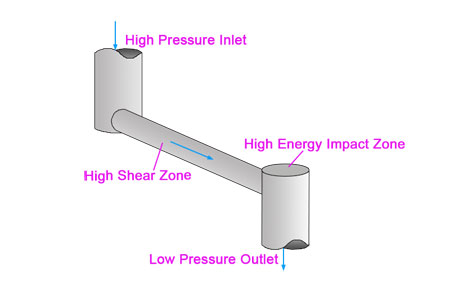

Figure 4 Single channel Z-type microjet diamond interactive cavity

Figure 5 Multi-channel Y-type microjet diamond interactive cavity

Figure 6 Multi-channel Z-type microjet diamond interactive cavity

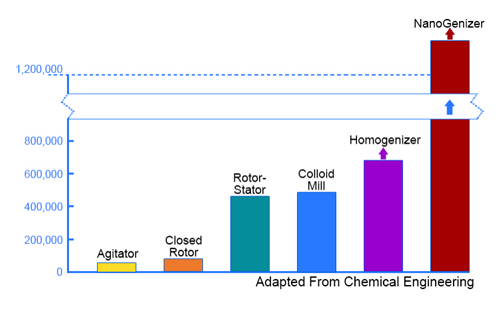

Feature 1. Very high shear force

After the liquid or solid-liquid mixture is pressurized by the power unit, the jet speed inside the microjet diamond interactive chamber can reach 500m/s, and the sound propagation speed exceeds 343m/s; The interior of the microjet diamond interactive chamber can be as small as 50um. The shear force experienced by the high-speed jet inside the diamond interactive chamber is high as in various equipment currently available.

Figure 7 Comparison of shear forces of different homogenization equipment The shear force of a

microjet high-pressure homogenizer on materials is unmatched by traditional valve type or other homogenization equipment.

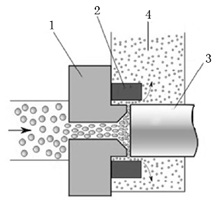

Feature 2 . Fixed internal structure and consistent reaction pressure

Figure 8 Schematic diagram of the internal structure of the homogenization valve (1-base 2-impact ring 3-spool 4-homogenized material)

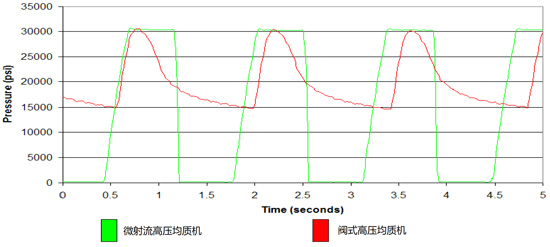

The diamond interactive chamber has a fixed internal shape and does not change with the change of pressure. The material passes through the diamond interactive chamber once, and the pressure is a constant peak during the process (as shown in the green curve in Figure 9); the homogenization valve has a dynamically adjustable structure. When the material of the homogenization valve type homogenizer passes through the homogenization valve, the pressure changes dynamically, and there is only a small proportion of pressure peaks (as shown in the red curve in Figure 9).

The particle size of the material processed by the microjet diamond interactive cavity decreases faster and has a narrower distribution.

Figure 9 Characteristics of pressure change curve during homogenization 3

. For

the application of jet Y-shaped pairs (Figure 3 and Figure 5), the mutual collision of the materials themselves is fully utilized, and the relative velocity of the two jets doubles at the moment when they collide, creating an explosion effect. The mutual collision between materials greatly reduces the wear and shearing of materials on the interactive cavity cavity and prolongs the service life of the cavity.

Feature 4 . good reproducibility

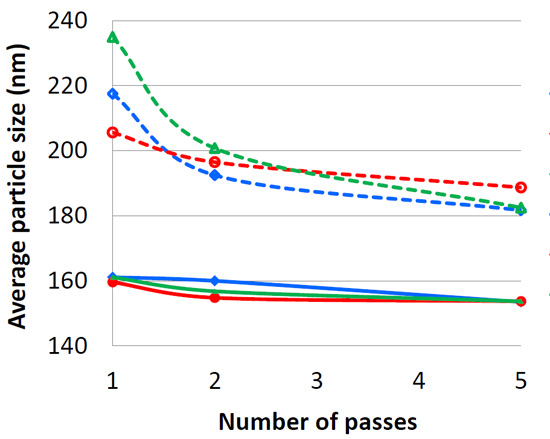

Figure 10 Comparison of the reproducibility of treatment effects between microjet high-pressure homogenizer and valve-type high-pressure homogenizer (taking fat emulsion samples as an example)

(dotted line is the results of three valve homogenizer treatments; solid line is the results of three microjet high-pressure homogenizer treatments)

Features 5. The

diamond interactive chamber (as shown in Figures 3 and 4) that can ensure the scaled-up production of a single channel is suitable for experimental microjet high-pressure homogenization equipment; the multi-channel diamond interactive chamber (as shown in Figures 5 and 6) is made of multiple diamond channels replicated in parallel. The replication of a single diamond channel ensures the consistency of the processing effect, and the increase in the number of channels ensures a larger processing flow rate within the same time.

Genizer in the United States is currently one of the only two companies in the world that supply microjet high-pressure homogenizers equipped with original microjet diamond interactive chambers. As a rising star, Genizer supplies microjet diamond interactive chambers. More and more colleagues learn from them. Industry colleagues such as PSI in Italy, Dyhydromatics in the United States, and Jinsystemtech in South Korea have successively equipped Genizer's diamond interactive chambers.

more details, please contact

| manager Wang Tel: 13020218906 Email: biotech@willnano.com Website: www.willnano.com Suzhou Microfluidic Nanobiotechnology Co., Ltd. |

苏州微流纳米Vic