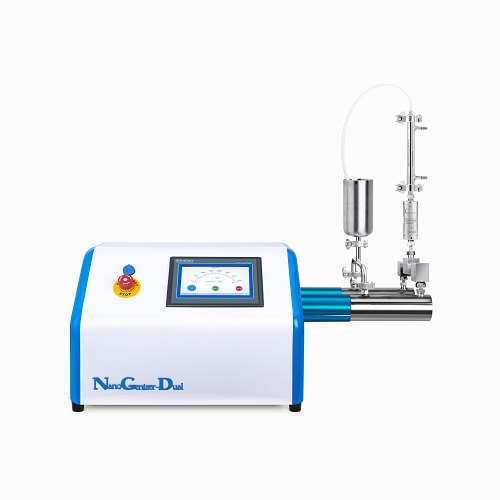

Product Details:

The NanoGenizer-Dual Homogenizer is a dual-pump desktop microjet electric homogenizer with touch screen operation and intelligent program control. Dual pumps can be used alone, or in parallel or series. It can be used in the laboratory to prepare liposomes, nanosuspensions, microemulsions, lipid microspheres, nanoprecipitates, nanoemulsions, nanocrystals, infusions, fine chemical reactions, etc. Up to the working pressure is 30000 Psi/2000 Bar. All parts in contact with the medium are 316L stainless steel, 17-4ph stainless steel, titanium alloy, tungsten carbide, PTFE, UHMWPE or other corrosion resistant materials.

Product parameters and characteristics:

1) Core technology: The application of the second-generation microjet diamond interactive chamber enables the NanoGenizer-Dual high-pressure homogenizer to combine the advantages of microjet, impinging stream and traditional high-pressure homogenization technology.

2) Homogenization pressure: NanoGenizer-Dual can reach a design pressure of 30,000 psi, and the touch screen controls pressure and operation.

3) Homogeneous flow rate: 180mL/min at 25,000 psi, 120mL/min at 30,000 psi (varies with pressure and material viscosity)

4) Small to sample volume: 30mL. You can set your own sample intake volume, so you don't suck and waste it!

5) Sanitary grade: Contact materials are all GMP, FDA-approved 316L and 17-4PH stainless steel, tungsten carbide, zirconium oxide and polymer polyethylene.

6) Temperature control: Sanitary heat exchangers can be equipped to effectively reduce material temperature and ensure activity.

7) Safety: The whole machine does not involve high-intensity air pressure and oil pressure, and is equipped with intelligent overload protection.

8) Modularity: Y and Z-type diamond interactive chambers can be optional, which can be used with a single pump, or dual pumps can be used in parallel or series.

9) Power supply: Applicable to 220V, certified by CE and ROHS standards.

10) size and weight: 72*43*33cm/60kg, the integrated design is flexible and light.

11) Features: On the microjet technology of diamond interactive cavities, the feasibility of parallel or series operation of samples is realized, which provides solutions for users 'various use needs, improves operating efficiency, and saves time and cost.

Examples of application areas:

More information:

1.& nbsp; Introduction to the working principle and characteristics of microjet high-pressure homogenizer

2.& nbsp; Genizer Microjet Diamond Interactive Cavity Use Guide

3.& nbsp; NanoGenzier-Dual Series Microjet High-Pressure Homogenizers User Manual