Product Details:

The NanoGenizer-Titanium microjet high-pressure homogenizer is a new generation of high-pressure homogenizer using an interactive chamber for jet diamond. It is also known as a nanohomogenizer. It can homogenize nanoemulsions, fat emulsions, liposomes, cell disruption, nanosuspension dispersion, particle reduction, and is widely used in pharmaceuticals, biotechnology, cosmetics, conductive pastes, graphene and other industries.

NanoGenizer-Titanium Microjet High-pressure Homogenizer

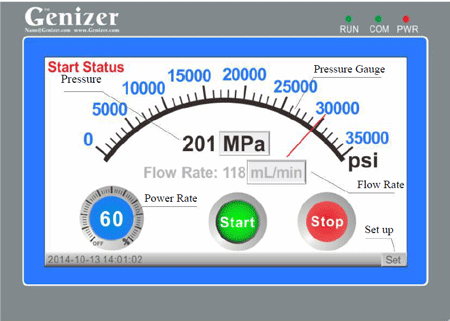

Experimental Microjet High-pressure Homogenizer PLC Control Interface

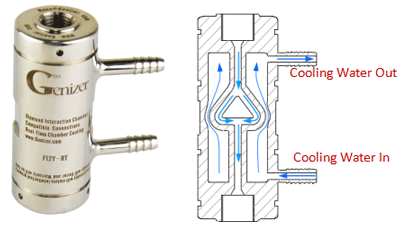

Microjet Diamond Interactive Cavity Core

| Specifications | |||||

| Model | NG-Ti-15K | NG-Ti-20K | NG-Ti-25K | NG-Ti-30K | NG-Ti-45K |

| Flow rate | 120mL/min | 120mL/min | 100 mL/min | 100mL/min | 60mL/min |

| down to sample size | 2mL | 2mL | 2mL | 2mL | 2mL |

| Up to pressure | 15,000psi | 20,000psi | 25,000psi | 30,000psi | 45,000psi |

| 尺寸(cm) | 75 × 40 × 35 | 75 × 40 × 35 | 75 × 40 × 35 | 75 × 40 × 36 | 75 × 40 × 38 |

| weight | 40 kg (85 lbs) | 40 kg (85 lbs) | 40 kg (85 lbs) | 45 kg (100 lbs) | 50 kg (110 lbs) |

| Up to temperature | 80ºC (176ºF) | ||||

| Voltage | 110V/220V | ||||

| Flush | to clean | ||||

| Application | Nano emulsion, Fat emulsion, Liposome, Cell Disruption, Nano dispersion, Deagglomeration | ||||

| 特征 | Digital display of pressure or pressure gauge | ||||

Product parameters and characteristics:

1 Core technology: The application of the second-generation microjet diamond interactive chamber enables the NanoGenizer-Titanium microjet high-pressure homogenizer to combine the advantages of microjet, impinging stream and traditional high-pressure homogenization technology.

2 Homogenization pressure: Up to the design pressure of 45,000 psi, touch screen controls pressure and operation.

3 Homogeneous flow rate: Up to 100ml/min (varies with pressure and material viscosity)

4 As small as sample size: 5ml, suitable for expensive materials. You can set your own sample intake volume, so you don't suck and waste it!

5 Low residual volume: About 1ml. The high-precision high-pressure cylinder pipeline design can control the residual volume to about 1ml without air blowing.

6 Sanitary grade: Contact materials are all GMP, FDA-approved 316L and 17-4PH stainless steel, tungsten carbide, zirconium oxide and polymer polyethylene.

7 Temperature control: Sanitary heat exchangers can be equipped to effectively reduce material temperature and ensure activity.

8 Safety: The whole machine does not involve high-intensity air pressure and oil pressure, and is equipped with intelligent overload protection.

9 Modularity: Y and Z-type diamond interactive chambers can be optional, and syringes can be directly used for material import and export or stainless steel hoppers can be switched.

10 Power supply: Applicable to 220V/50Hz, 1.8Kww, CE and ROHS standard certification.

11 size weight: 80*36*40cm/45kg, the integrated design is flexible and light.

Examples of application areas:

More information:

2.& nbsp; Genizer Microjet Diamond Interactive Cavity Use Guide.

| manager Wang Tel: 13020218906 Email: biotech@willnano.com Website: www.willnano.com Suzhou Microflow Nanobiotech Co., Ltd. |