Product details:

Genizer microjet diamond interaction chamber, also known as diamond homogeneous chamber, counter-jet microjet diamond homogeneous chamber, Diamond Interaction Chamber, Diamond Reaction Chamber, and DIXC. The American Genizer diamond microjet diamond interactive chamber has the world's nanodispersion processing capabilities, extremely high result reproducibility, and guaranteed scaled-up production performance. It is recognized and purchased by peers in the field of microjet homogenization around the world, from the United States, Italy, and South Korea. With their counterparts in microjet homogenization equipment, they purchase nearly 100 Genizer microjet diamond interactive chambers every year.

Different specifications of Genizer diamond homogenization chambers

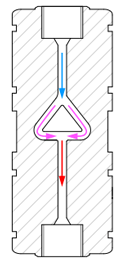

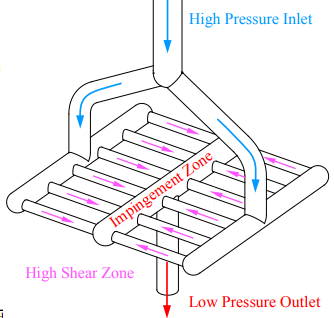

The Genizer diamond homogenization chamber is the core of the new generation of microjet high-pressure homogenization equipment. It has an overall modular design, a fixed internal shape, no moving parts, and no need to adjust the valve clearance like a homogenization valve. It has diversified flow channel design and is divided into Y-type counterjet and Z-type impact. There are two large series of models with corresponding aperture sizes in different series to match the needs of different homogenization applications. The use of diamond materials and the Y-type microjet diamond interactive cavity make full use of the sonic speed (speed can reach ~500m/s) to produce explosive effects in the instant of high-speed self-phase collision of materials, which reduces the wear of materials on the cavity and greatly increases the service life of the cavity.

Suzhou Microfluidic provides all models of Genizer microjet diamond interactive chambers, from small test experiments to industrial production, suitable for high-pressure homogenizers such as MFIC,BEE,PSI, etc. Genizer microjet diamond interactive chambers are exported to all over the world with their unique homogenization effect, high cost performance and customized services. It mainly serves industries such as pharmaceuticals, biotechnology, cosmetics, and high-tech nanomaterials. Recently, the beverage industry has paid attention to microfluidic technology, which will also help some manufacturers take the lead in occupying the share of high-end beverages.

Principle of action of Genizer microjet diamond interactive chamber (Genizer homogeneous chamber):

When the material passes through the diamond interactive chamber, it is at high pressure (up to 60000psi/4000bar/400MPa), a high-speed microjet is formed through a very small pore channel (less than 100 microns), with a speed of up to 500m/s (Transonic speed 340m/s), after processing through severe shearing, oscillation, collision, cavitation effect and counter-injection, the material changes in physical, chemical, structural properties, etc., and eventually the particle size is reduced and the distribution is narrow. Homogeneous effects such as increased stability, uniformity and transparency.

Inside the Y-shaped micro-jet diamond interaction chamber, the relative velocity of the two sonic jets doubles at the moment of collision, creating a high-explosive effect. The mutual collision between materials greatly reduces the wear and shearing of materials on the interactive cavity cavity and prolongs the service life of the cavity; the microjet high-pressure homogenization technology combines the advantages of microjet, impinging stream and traditional high-pressure homogenization technology., with higher homogenization efficiency.

Schematic diagram of the working principle of Genizer diamond homogeneous cavity

Genizer Microjet Diamond Interactive Chamber (Genizer Homogenization Chamber) Product parameters:

1 Pressure range up to 60,000 PSI(4500Bar/450MPa)(related to the aperture of the interactive chamber and material viscosity);

2 Hygiene level: The materials used are FDA-approved 316L stainless steel and diamond;

3 Interface: 1/4" and 3/8" cone tube threads are matched with Hip high-pressure connectors, which can be customized;

4 Temperature control: Materials with temperature requirements can be selected for models with jacketed real-time cooling function;

5 Compatibility: Suitable for high-pressure homogenizers such as Microfluidics, Genizer, PSI, Avestin and BEE.

6 Commonly used single channel microjet diamond interactive cavity models: F12Y, F20Y, J20Y, G10Z, H10Z, H210Z, H30Z

7 Commonly used multi-channel microjet diamond interactive cavity models: F20Y-6, F20Y-7, H10Z-5, H10Z-6, F12Y-8, F12Y-11

Various models of microjet diamond homogenization cavities

Application of Genizer Microjet Diamond Interactive Cavity (Genizer Homogeneous Cavity):

Preparation of fat particles, microemulsions, liposomes, suspensions and microcapsules in the pharmaceutical industry;

cell disruption, extraction and homogenization of intracellular and external substances in bioengineering products;

homogenization and emulsification of food and beverage industry products to improve product stability;

Homogeneous dispersion of products in cosmetics, fine chemicals and other industries;

nano-agglomeration of new energy materials;

production and preparation of graphene, conductive pastes, and resistive pastes.

more details, please contact

| manager Wang Tel: 13020218906 Email: biotech@willnano.com Website:www.willnano.com Suzhou Microfluidic Nanobiotechnology Co., Ltd. |