苏州微流纳米生物技术有限公司

The microjet high-pressure homogenizer is equipped with a microjet diamond interactive chamber with micron channels to perform extremely high shearing, pressure drop, cavitation, collision and anti-jet explosion on materials that have been accelerated at high pressure at supersonic speeds (up to 500m/s).

The fixed internal shape of the microjet diamond interactive cavity ensures that the material receives the same force every time under the same pressure and passes through the interactive homogenization cavity, thus obtaining completely repeatable processing results; the replication and expansion of the single diamond microchannel with the same shape ensures consistent effects while increasing production capacity.

Microjet high-pressure homogenizer is suitable for preparing nanoemulsions, microemulsions, liposomes, microspheres and monodispersion of various nanomaterials. This article will briefly introduce a case of nanodispersion of materials using a microjet high-pressure homogenizer.

Figure Microfluidic High-pressure Nanodispersion

Instrument and Sample

Pilot Microfluidic High-pressure Homogenizer Suzhou Microfluidic Nano-Biotech Co., Ltd. supplies

Genizer Laser Nano-Particle Size Meter Suzhou Microfluidic Nano-Biotech Co., Ltd. supplies

analytical balances

to send samples to customers (to be dispersed, nanomaterials with uniform particle size, quickly agglomerated and settled after dissolution in solvent)

Customer-specified solvent

Figure Genizer Laser Nano-Particle Size Meter

Experimental Steps and Results:

1.& nbsp; Weigh the required amount of nanomaterials, dissolve them in a specific solvent, and prepare a suspension of 25% mass to volume ratio (including materials + excipients). Due to the extremely high specific surface area and extremely high collision speed of nanomaterials, obvious agglomeration and precipitation can be seen at the bottom of the beaker when the configured sample is left standing for 10 seconds.

Figure After configuration, nanomaterial samples quickly gather and settle

2.& nbsp; After cleaning the microjet high-pressure homogenizer, the material is magnetically stirred, and the sample is injected with a Luer hose while stirring. After passing through low pressure, the sample is pre-dispersed, and the settlement becomes significantly slower, not as easy as when it was first prepared. Settle and gather.

3.& nbsp; Increase the micro-jet processing pressure, carry out high-pressure micro-jet nano-dispersion, select the appropriate number of times and pressure, and explore better processing conditions.

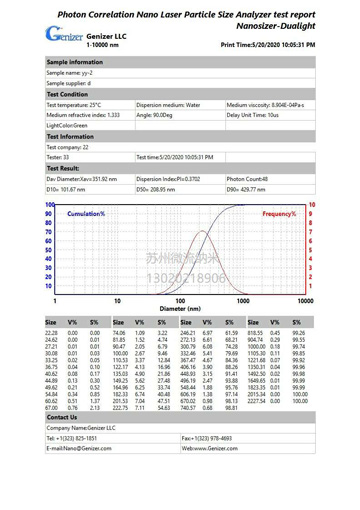

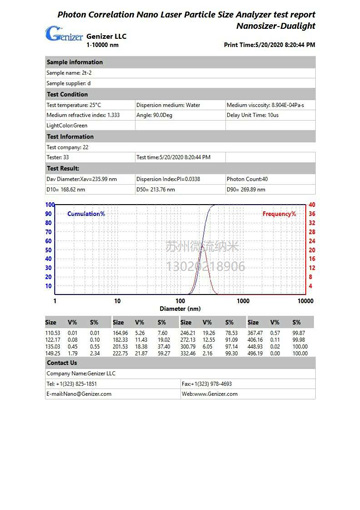

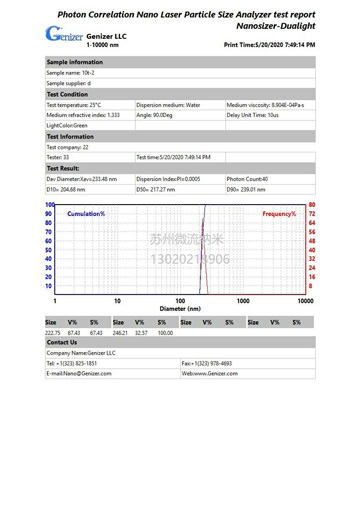

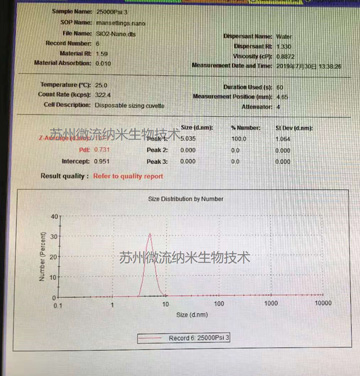

4.& nbsp; Test the dispersion effect of the sample using a Genizer nanoparticle.

图 Test results of particle size distribution of nanomaterials dissolved in solvent

Figure Particle size distribution of material after microjet nanodispersion treatment

TudorParticle size distribution of material after secondary microjet nanodispersion treatment

Figure Dispersion results of nano-microsphere materials with different particle diameters (dispersion results of original materials with other particle diameters)

The customer's powder is a nano-microsphere material with a handsome particle size. It can be seen from the above particle size test results that when dissolved in the solvent, the sample particles are aggregated and the particle size distribution is wide. The results of a few treatments show that the agglomerated particles have been dispersed in a high proportion. However, after multiple treatments, the peak shape is approximately a needle, and the PDI is extremely small, indicating that the sample is almost completely monodisperse.

1-300nmNanomaterials with particle size have extremely small particle size, high specific surface area, and high collision probability, causing some nanomaterials to rapidly aggregate and settle when dissolved in solvent. However, because the particle size is too small, ordinary equipment cannot measure nanomaterials. Fully disperse, affecting the performance of nanomaterials. However, a microjet high-pressure homogenizer equipped with a microjet diamond interactive cavity, with its extremely high nanodispersion ability, can10nmThe following nanomaterials are fully monodispersed, 100nm-300nmGrade materials can achieve good nano-dispersion effect.

more details, please contact

| manager Wang |

苏州微流纳米Vic