苏州微流纳米生物技术有限公司

The microjet high-pressure homogenizer supplied by Microfluidics in the United States is equipped with a microjet diamond interactive chamber of the same model as the Genizer microjet high-pressure homogenizer in the United States. Microfluidics M7250 microjet homogenizer series is a production-type microjet homogenizer commonly used by pharmaceutical companies. The instrument is designed to have a pressure of 30000psi and a flow rate of about 240L/h (which varies up and down depending on the nature of the material). This equipment is suitable for the production of liposomes, nanoemulsions, paclitaxel albumin, injections and other products, as well as cell wall breaking and other processes.

A few days ago, Suzhou Microflow Nanobiotech Co., Ltd. received an emergency equipment repair report from the customer unit M7250. Engineering personnel rushed to the scene overnight to carry out equipment troubleshooting and maintenance.

Initial equipment problem: The operating frequency of the plunger pump of the M7250 high-pressure cylinder is unstable and will gradually slow down as the running time of the machine increases. In the start-up test, the operating frequency starts at about 40 times under the homogeneous pressure of 24000PSI. After running for more than ten minutes, the frequency will drop to about 38 times, and if it continues to run for more than an hour, it will drop to about 33 times, which seriously affects the stability of the production process.

Failure cause analysis: The equipment has good appearance and no obvious damage. The start-up and running condition is good, there is no obvious liquid leakage or leakage in each component, the hydraulic pressure is very stable, and the hydraulic oil temperature is also in the normal range. Since the operating frequency of the plunger pump of the high-pressure cylinder is directly related to the power unit of the equipment, first consider whether the power unit part will attenuate as the operating time increases, and the following two main considerations are made:

1. Does the flow rate of the hydraulic piston pump continue to decrease during operation, causing the frequency of the high-pressure cylinder piston pump to decrease?

2. Insufficient compressed air flow and pressure driving the pneumatic reversing valve cause the frequency of the high-pressure cylinder plunger pump to decrease?

After screening and eliminating factors in the power unit, the output condition factors of the high-pressure cylinder plunger pump were investigated. The following two inspections were mainly carried out:

1. Due to insufficient supply of cooling water for the seal ring of the plunger pump or too high temperature of the processed material, the seal ring Excessive expansion increases the frictional resistance of the plunger pump, which in turn affects the operating frequency?

2. Because each stroke of the high-pressure cylinder plunger pump is certain, the discharge flow of the equipment is proportional to the operating frequency. Is there any residue that continues to block the microporous channels of the diamond interactive chamber, causing the flow to continue to decrease?

After screening, the cause of cooling was ruled out. Screening for blocking of diamond interactive cavities: After fully recoiling the four interactive cavities, it was found that the operating frequency of the equipment could be restored to the original 40 times (when the equipment was stopped for one hour and started running, it was found that the frequency could not be restored), and the frequency continued to decrease steadily. Since backflushing is a typical operation of microjet homogenizers to remove blockages in the interactive chamber, factors in the diamond interactive chamber are locked for in-depth investigation.

Suzhou Microfluidic Nanoengineers conduct Microfluidics 7250 equipment maintenance

Fault handling:

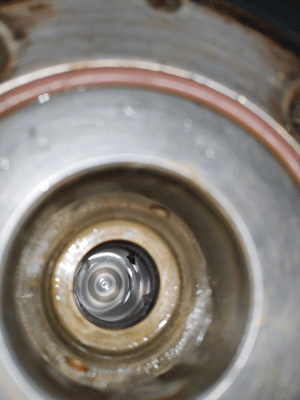

First disassemble the pipeline of the interactive chamber component and find that there is obvious particulate residue in the pipeline. Then disassemble all the pipelines in contact with the material for inspection: including two high-pressure cylinders, material inlet components, and material transmission pipelines. The plunger has obvious friction marks. After the high-pressure cylinder was removed, it was found that the plunger sealing ring had obvious wear and coking.

Clean the interior of the high-pressure cylinder with the removed copper ring and plunger seal ring

, replace it with two spare sets of copper rings and seal rings, and use alcohol to acoustically clean the rest of the materials in contact with the pipeline. Reassemble the pipeline but not first. Install the interactive cavity component and use ddH2O to clean it when starting and running. The old original chamber was returned to the factory by Suzhou Microfluidic Nanoengineering personnel for repair. After replacing the new Genizer Microfluidic Diamond Interactive Chamber, the equipment problem was successfully solved.Clean the interior of the high-pressure cylinder with the removed copper ring and plunger seal ring

, replace it with two spare sets of copper rings and seal rings, and use alcohol to acoustically clean the rest of the materials in contact with the pipeline. Reassemble the pipeline but not first. Install the interactive cavity component and use ddH2O to clean it when starting and running. The old original chamber was returned to the factory by Suzhou Microfluidic Nanoengineering personnel for repair. After replacing the new Genizer Microfluidic Diamond Interactive Chamber, the equipment problem was successfully solved.

Other equipment issues and maintenance suggestions:

1.& nbsp; Since the equipment has been in long-term stagnation and operations have been carried out in changing locations, recommendations:

1.1 Since the hydraulic system variable piston pump has high requirements for the cleanliness of hydraulic oil, it is recommended to replace the hydraulic oil and filter elements

1.2 It is recommended to clean and maintain the entire equipment.

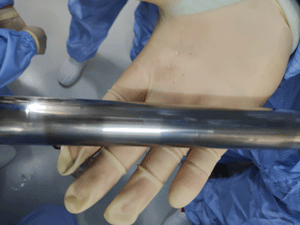

2. Both plunger rods have severe scratches caused by friction with the copper ring, causing the cooling water of the plunger seal to leak. The scratched plunger rod will reverse wear the plunger seal ring, resulting in a greatly shortened service life of the seal ring. Residue is introduced again to block the interactive cavity.

Both plunger rods have obvious drawing scratches. Normally, the plunger rods are clean and

shiny. It is recommended to replace the two plunger rods and the corresponding cooling water seals.

3. The homogeneous pressure sensor of the equipment is damaged and it is recommended to replace it.

4. It is recommended to add a water flow regulating valve to the cooling water of the product heat exchanger to control the product to be cooled within a constant range (Note, when the cooling water temperature provided by the customer is too low and the real-time flow rate of the product homogenization is too low, icing will occur and affect the homogenization efficiency).

5. The flow test of the original interactive cavity of the equipment is too large. The micro-channel may become larger due to wear. It is recommended to replace or repair it, and purchase a spare interactive cavity.

6. It is recommended to reserve some high-pressure valve parts, pipe fittings and common sealing rings to prevent the long procurement process from affecting production after damage.

7. It is recommended to provide operators with training on the use of microfluidic equipment, including equipment principles, operating steps, fault diagnosis and common precautions.

8. It is recommended to form an annual maintenance plan, regularly check the use status of equipment, and regularly replace wearing parts to keep the equipment in good condition.

苏州微流纳米王