苏州微流纳米生物技术有限公司

Graphene's unique mechanical, thermal, optical, electrical, magnetic and other characteristics make it have huge application potential in the fields of microelectronics, biosensors, energy storage materials and composite materials.

Mechanical stripping of graphene has fewer defects and a relatively complete structure than graphene prepared by other chemical methods. This article will briefly introduce the application of microjet high-pressure homogenization method in the preparation of graphene.

Main instruments and raw materials:

graphite raw material samples sent by customers of Genizer Microjet High-Pressure Homogenizer in the United States

Pre-experimental steps and results:

1) Divide 2 portions of the mixed raw material samples into 2 sample bottles, each with 20ml;

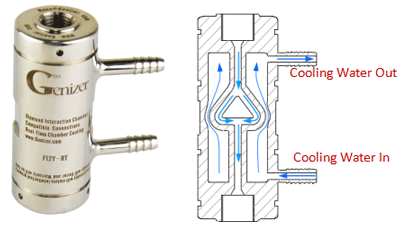

2) Select and install a F140Y-RT diamond interactive chamber, and connect it to a microjet high-pressure homogenizer and a real-time cooling system;

3) No treatment was given to the control group, and the experimental group was homogenized for 10 times at 20,000 psi;

4) Appearance observation of treated samples and control groups

Figure 1 Before homogenization (left), after high-pressure homogenization (right)

The sample after high-pressure homogenization with microjet is like the state of Amushi yogurt, with low mobility and high viscosity. A drop of sample firmly hanging on the mouth of the cup can be seen in the right beaker. After processing, the volume of the sample becomes larger. Under the same reaction times, the higher the reaction pressure, the larger the volume of the sample expands. In addition, when the samples were tilted, the control group had high mobility, and the experimental group had serious wall hanging after tilting.

5) Observation of the microscopic shape of the sample

Figure 2 Electron microscope test results returned by the customer (few layers of graphene)

Principle of microjet high-pressure homogenization:

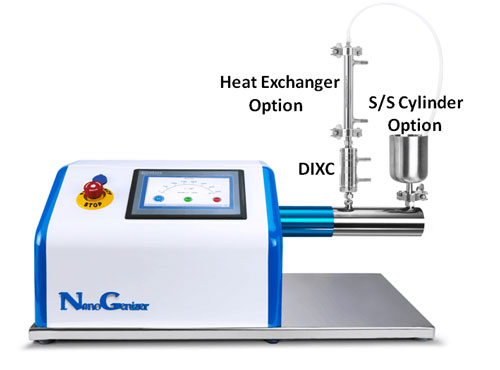

1) The microjet high-pressure homogenizer consists of a power unit and a homogenization core (diamond interactive chamber).

Figure 3 Microjet high-pressure homogenizer (red circle: power unit, touch screen, blue circle: diamond interactive chamber)

2) The core of the microjet high-pressure homogenization technology in this experiment lies in the diamond interactive chamber of the microjet high-pressure homogenizer:

Figure 4 Single channel temperature-controlled diamond interactive cavity object (left), schematic diagram of internal structure (right)

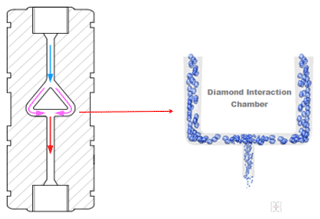

Figure 5 schematic diagram of microjet high-pressure homogenization principle

The Y-type diamond interactive chamber has a fixed internal structure. After pressurized, graphite liquid passes through hundreds of micron holes to form sonic jets (up to 1000m/s-1500m/s), which occur inside the Y-type diamond interactive chamber. Severe shearing, collision, cavitation and counter-jet effects are generated (unlike a single channel, the relative speed of the two jets doubles at the moment of collision, creating a counter-jet explosive effect). For the application of jets, the mutual collision between materials is fully utilized, which greatly reduces the wear and shearing of materials on the interactive cavity cavity and extends the trial life of the cavity; the micro-jet high-pressure homogenization technology integrates micro-jets, impinging flow and The advantages of traditional high-pressure homogenization technology are integrated into one, with higher homogenization efficiency.

Users of the Chinese Academy of Sciences system have successfully used the Genizer microjet high-pressure homogenizer to produce monolayer graphene. Suzhou Microfluidic Nanosupply Experiment to Production-type Microfluidic High-pressure Homogenizer can achieve efficient and highly reproducible scale-up production by increasing the number of channels in the diamond interactive chamber. If you have technical discussions or instrument trial needs, you are welcome to contact and compare the equipment processing effects. Everything is effect-oriented.

| Manager Wang Tel: 13020218906 Email: biotech@willnano.com Website: www.willnano.com Suzhou Microflow Nanobiotech Co., Ltd. |

苏州微流纳米Vic