苏州微流纳米生物技术有限公司

What is the difference between a high-pressure microjet homogenizer and a high-pressure homogenizer? What are the working principles of high-pressure microjet homogenizer and high-pressure homogenizer? When is it suitable to use a microjet homogenizer? When is it suitable to use a high-pressure homogenizer? In the preparation of nanoemulsions and liposomes, what are the similarities and differences between microjet homogenizers and high-pressure homogenizers?

Figure Appearance of common high-pressure homogenizers

Figure Appearance of common high-pressure micro-jet homogenizers

First of all, the core differences between high-pressure micro-jet homogenizers and traditional high-pressure homogenizers are briefly introduced:

1.& Core components:

Core components of traditional high-pressure homogenizer: split slit-type homogenization valve;

core components of micro-jet high-pressure homogenizer: diamond interactive chamber with fixed internal shape, also called micro-jet homogenization chamber

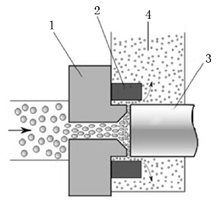

Figure Split slit homogenization valve for high-pressure homogenizer (1-valve seat 2-impact ring 3-valve core 4-homogenized material)

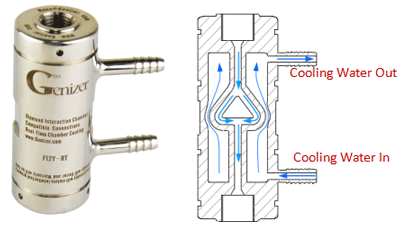

Figure Microjet diamond interactive chamber for microjet homogenizer

1.1 The homogenization valve equipped with high-pressure homogenizer is generally divided into three components: homogenization valve seat, homogenization valve core and impact ring.

The homogeneous valve seat and the homogeneous valve core are bonded in advance. When the power unit of the homogenization equipment sucks and conveys the sample to the homogeneous core, the sample is squeezed into the pore channel of the homogeneous valve seat from the front flow channel. Since the pore channel of the homogeneous valve seat (generally in diameter: 1mm~3mm) is much smaller than that of the front flow channel pipe, the sample accelerates rapidly and squeezes the homogeneous valve seat and the homogeneous valve core into a gap. Sample particles are sprayed out at high speed from this gap and are ejected after being impacted by the inside of the impact ring., completing the homogenization process.

During the homogenization valve processing of samples, 1) there is a pressure drop (above 1000bar) at the moment of ejection from the slit;2) the impact force between the sample and the inside of the impact ring and the shear force between the particles after ejection, so that the particles achieve the effect of reducing the particle size.

The size of the slit between the homogeneous valve seat and the homogeneous valve core during the process directly affects the resistance that the sample withdraws through the gap. The size of this resistance is the homogeneous pressure. Generally speaking, the greater the resistance, the higher the homogeneous pressure. The higher the ejection speed, the stronger the shear force between particles and the impact ring, the stronger the homogenization ability and the smaller the particle size. The adjustment of the homogenization pressure is achieved by adjusting the distance between the homogenization valve seat and the homogenization valve core through a handwheel.

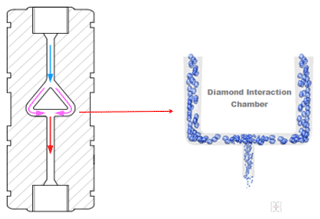

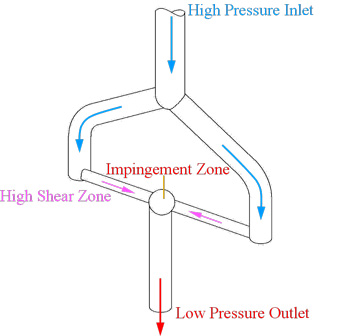

1.2 The internal structure diagram of the fixed internal shape diamond interactive cavity type

microjet interactive cavity (the actual channel shape is relatively more complex)

Different from the homogeneous valve type split design, the microjet diamond interactive cavity is an integral internal structure fixed Y or Z-type microchannel, with pore sizes ranging from 50um to several hundred microns. The original interaction cavity channel material was ceramic, but was later replaced by diamond material.

The principle is that after the liquid-liquid or solid-liquid suspension sample is pressurized by the power unit, it is partially accelerated through the front channel of the diamond interactive cavity. The jet speed reaches 500m/s when it reaches the diamond channel. The high-speed jet like a bullet passes through the fixed shape of the diamond microchannel. Through high-frequency shearing + impact + collision + anti-blasting between material particles + huge pressure drop (up to 2000bar or higher), the material particle size is finally refined and uniform.

The homogenization valve type homogenization equipment uses a handwheel to adjust the tightness between the homogenization valve seat and the valve core to change the gap size and thereby change the homogenization pressure to change the homogenization effect. The size of the reaction microchannel in the microjet interactive chamber is fixed, and the adjustment of its homogeneous pressure is achieved by adjusting the motor frequency and controlling the adjustment of the flow rate. That is, when the slit channel is fixed, the larger the flow rate, the higher the pressure, the stronger the shear and collision forces, and the better the homogenization effect.

Due to the huge shear, explosion and impact during the homogenization process of microjets, in addition to the energy required for homogenization and crushing, part of the total energy must be converted into heat. The higher the homogenization pressure, the more heat generated in an instant. For temperature-sensitive sample processing, a material heat exchanger is required, and the sample can be cooled by connecting a refrigerant at a specific temperature.

2. Comparison of the application of microjet homogenizer and high-pressure homogenizer in the preparation of liposomes and nanoemulsions

2.1 Particle size reduction

Since the liposome sample is a lipid bilayer formed with phospholipids as a membrane material, the liposome particles are highly flexible, and the energy required to reduce the particle size is not large; nanoemulsions are mostly water-oil mixed and do not have great rigidity. For particle size reduction, both types of homogenization equipment can meet the requirements of ordinary liposome samples to reduce the particle size. For samples with relatively small particle size requirements, the effect of the microjet homogenizer is better than traditional high-pressure homogenizer.

2.2 PDI Control

In addition to particle size, liposome and nanoemulsion samples have very high requirements on particle size distribution. Generally, PDI needs to reach 0.2 or below 0.1. PDI corresponds to the uniformity of the sample, and the homogenization equipment of the microfluidic interactive cavity has great advantages, mainly because: The piston in the power part of the microjet diamond interactive cavity equipment has a small diameter and a long stroke. The homogeneous output is high pressure lasting for a long time and stable pressure. The inner diameter of the channel is very small, so its energy conversion rate is high and the pulse fluctuation is very small. The process conditions under which the sample particles pass through the microjet interactive cavity are basically the same, so the PDI of the homogeneous sample is generally small and can directly meet the requirements.

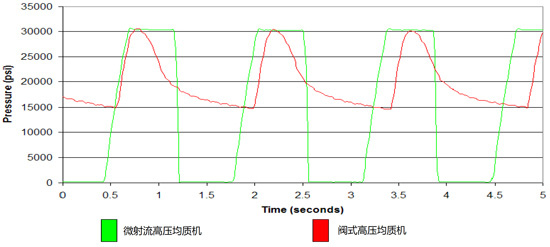

However, the homogenization valve type homogenization equipment has poor particle size uniformity due to the thick plunger, short stroke, large pressure pulse fluctuations. The average particle size of the homogenized sample can often meet the requirements, but the PDI often has a certain gap with the expected effect. The pressure waveform of the homogeneous equipment with micro-jets and diamond intercavities has a ladder shape, and the rise and fall time is very short, while the pressure of the homogeneous valve type equipment is similar to a sine wave and fluctuates greatly.

Figure Pressure changes between microjet homogenizer and high-pressure homogenizer during the homogenization process

. Of course, the homogenization valve type homogenization equipment is characterized by moderate homogenization pressure, but the flow rate is much larger than that of microjet cavity type homogenization equipment, so when it is used for homogenization of liposome samples, the time required for the homogenization process can be greatly reduced.

2.3 Results Repeatability and scale-up production

As mentioned above, when the sample is processed through the microjet high-pressure homogenizer, it passes through the same type of diamond interactive chamber under the same pressure, and the sample is subjected to basically the same process conditions. Compared with the split slit design homogeneous valve (which has more process variables present), the sample processing results are also more repeatable.

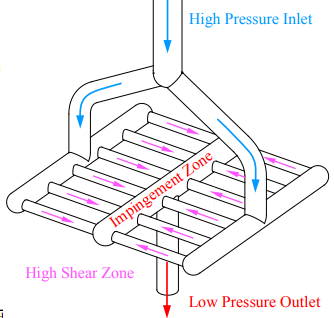

For the split slit high-pressure homogenizer, the slit structure needs to be expanded from small test to scale-up production. Compared with the homogenization valve in small test, the enlarged homogenization valve introduces more variables and the flow rate can be reduced to a very large size. However, the effect after scale-up is difficult to ensure the same as that in small test; The microjet homogenizer of the microjet interactive cavity type achieves the same effect by copying the single-channel diamond interactive cavity and the microchannel into a multi-channel diamond interactive cavity (the conventionally used diamond interactive cavity can reach 11 channels). Premise, the equipment has greater production capacity.

Figure Schematic diagram of the internal structure of single-channel microjet diamond interaction cavity and multi-channel microjet interaction cavity for

more details, please contact us

| manager Wang |

苏州微流纳米Vic