产品详情:

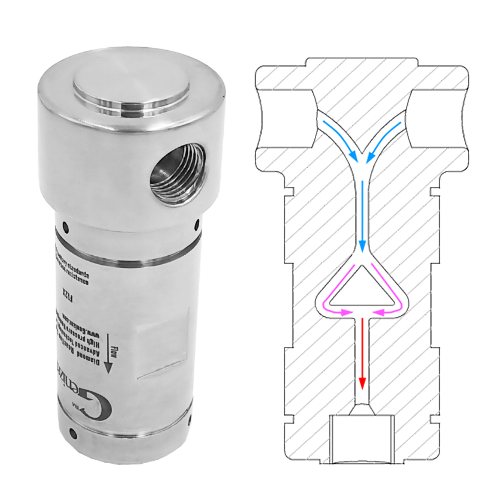

Product name: High-pressure cross-injection microfluidic mixing and homogenization instrument

English name: High Pressure Micromix Homogenizer

Other names: High-pressure multi-component microfluidic equipment

Product model: MixGenizer

High-pressure microfluidic mixing homogenizer

Mixgenizer Ultra-high pressure microjet homogenizer Pilot

multi-channel microfluidic interactive cavity principle

Product parameters and characteristics:

1 Core technology: The application ofmulti-channel microfluidic diamondinteractive chambersenables the Genizer high-pressure microfluidic hybrid homogenization instrument to combine the advantages of microfluidic and traditional high-pressure homogenization technologies.

2 Mixing pressure: Up to the design pressure of 30,000 psi, touch screen controls the pressure and multi-component injection speed.

3 Mixing flow rate: Up to 100mL/min (flow rate can be adjusted and varies with pressure and material viscosity).

4 Mixing type: 2-component mixing reaction homogenization, optional 3-component or 4-component mixing reaction homogenization.

5 Mixing accuracy: 1%, accurately control the mixing ratio.

6 Injection speed: 0-100mL/min± 0.1 mL/min, accurately control the feed ratio and injection speed.

7 Mixing ratio: 25%-400%.

8 Sanitary grade: Contact materials are all GMP, FDA-approved 316L and 17-4PH stainless steel, tungsten carbide, zirconium oxide and polymer polyethylene.

9 Temperature control: Sanitary heat exchangers can be equipped to effectively reduce material temperature and ensure activity.

10 Modularity: Optional dual, triple or four-channel microfluidic interactive chambers and corresponding 2, 3 or 4 high-pressure pumps. Syringes can be used directly or stainless steel hoppers can be switched at the inlet and outlet of materials.

11 Appearance: Stainless steel shell, pharmaceutical grade hygiene standard.

12 Application: Preparation of liposomes by cross-jet; one-step emulsification method mixes the oil phase and the water phase in proportion.

Examples of application areas:

| manager Wang Tel: 13020218906 Email: biotech@willnano.com Website: www.willnano.com Suzhou Microfluidic Nanobiotechnology Co., Ltd. |