苏州微流纳米生物技术有限公司

In mid-December 2020, engineers from Suzhou Microfluidic Nanobiotechnology Co., Ltd. went to Northwest A & F University to install and train high-pressure microjet nanohomogenizers, and conduct on-site sample processing.

The teacher's samples had been processed with a traditional valve-type high-pressure homogenizer before. During the on-site installation of Suzhou Microflow's NanoGenizer high-pressure microjet nanohomogenizer, the teacher was very curious about how this equipment would work. Is it different from the equipment used before? Samples were prepared on site and processed and tested by themselves.

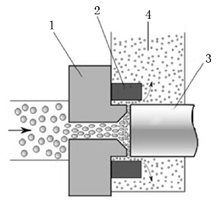

The valve-type high-pressure homogenization equipment used by the teacher before is the mainstream split valve high-pressure homogenizer. The core processing component of the equipment is the homogenization valve (the pressure is adjusted by adjusting the gap between the impact ring of the valve body and the valve seat through the handwheel),

Figure Schematic diagram of the homogenization valve structure (1-valve seat 2-impact ring 3-valve core 4-homogenized material) The

used high-pressure homogenizer can only process 50ml in a single time, requiring multiple sample additions;

Adjust the pressure handwheel When screwing, it was not continuous, breaking a homogenization valve. Although the homogenization valve is also made of diamond, the split structure greatly reduces the durability of the diamond homogenization valve body;

When repeating the experiment, the same parameters were set, but the results could not be repeated. I was very frustrated after several experiments...

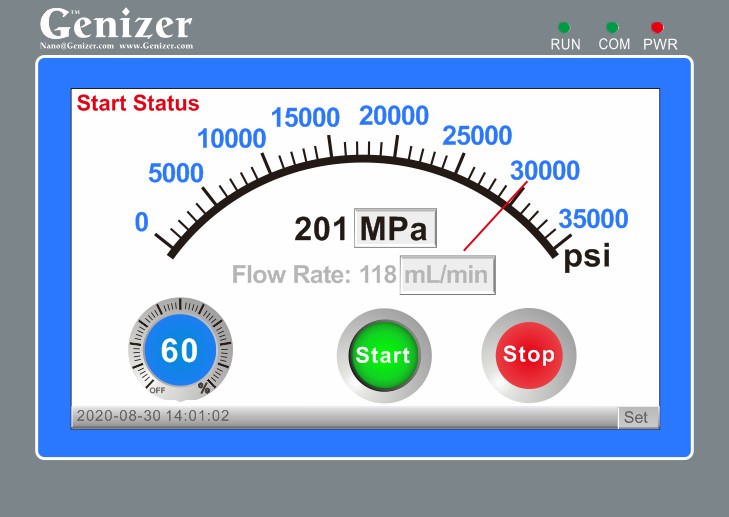

The core is the NanoGenizer 30K high-pressure microjet homogenizer with a microjet diamond interactive chamber. It is highly modular and uses the touch screen to set parameters and adjust pressure:

Support processing of small quantities such as a single 5ml sample (support self-setting of reaction parameters such as inhalation volume), and at the same time switch between Luer syringe (a very small quantity of samples), Luer steel cup (several hundred ml), and Luer hose (several liters of samples continuously processed), which can meet the rapid switching from very small quantities to continuous processing methods;

Figure The injection mode of NanoGenizer high-pressure microjet homogenizer switches

the PLC touch screen to control the pressure, and there is no need to manually adjust the handwheel to control the pressure. Three touch screen buttons complete an approximate "fool" operation;

Figure NanoGenizer High-pressure Microjet Homogenizer Touch Control Screen

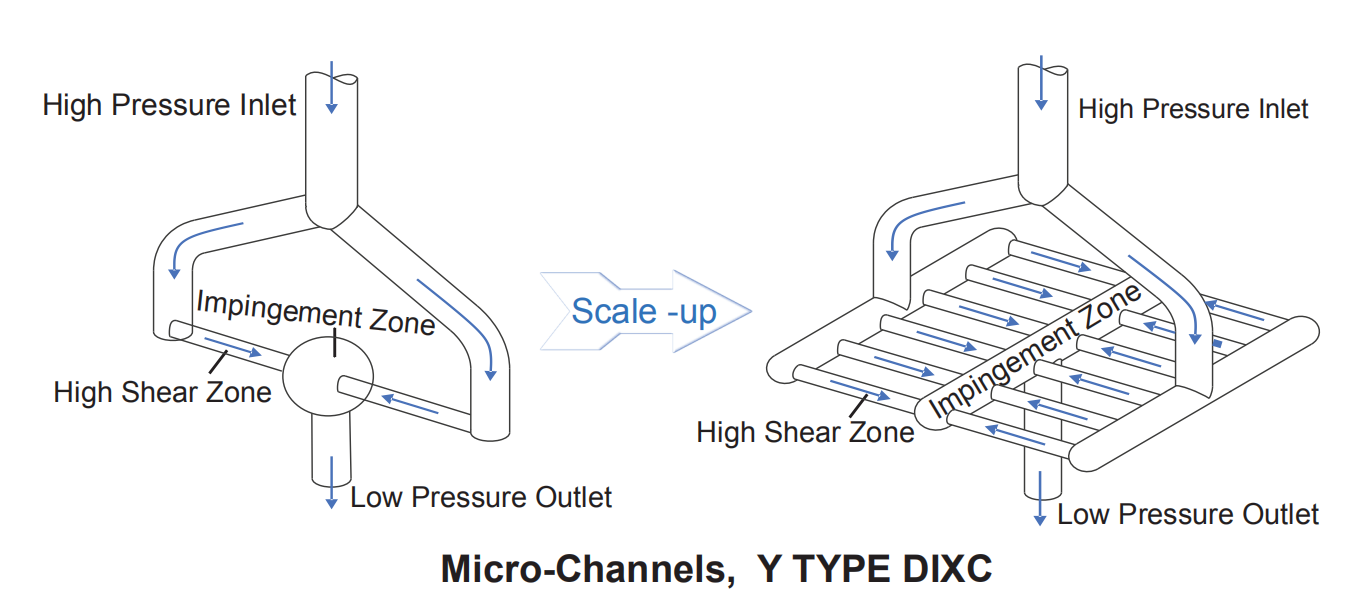

The interior of the microjet diamond interactive chamber is a fixed shaped microporous channel with no moving parts, and there is no small deformation during the processing process. The processing results are extremely repeatable. On the premise of optimizing the formula, the first treatment process to obtain high-quality results. As long as the same conditions are used next time, extremely repetitive results will be obtained...

Figure Structure schematic diagram of single-channel microjet diamond& interactive cavity

After the same sample was processed on site, the appearance of the sample after three treatments with the Nanogenizer 30K microjet high-pressure homogenizer was similar to the previous six better results, and the particle size distribution was even narrower. Subsequent stability tests of new dairy products are expected to have a better result.

The two words that the teacher kept saying during the sample processing process were: ""! The feeling of using equipment can be summed up as: I hate meeting the equipment too late. By truly comparing the Genizer high-pressure microjet nanohomogenizer with the ordinary high-pressure homogenizer, you can personally feel the difference between the two.

Unincidentally, teachers from multiple units have responded, and the results processed with high-pressure homogenizers are often irreproducible, one result at a time, which greatly reduces the credibility of the experimental results;

actually comparing the use of high-pressure homogenizers and NanoGenizer high-pressure microjet homogenizers, teachers of NanoGenizer high-pressure microjet homogenizers generally feel that Nanogenizer high-pressure microjet homogenizers is simple to operate, more efficient, and more repetitive than traditional high-pressure homogenizers;

More importantly, when some teachers process high-end complex samples, they only get satisfactory results after using the NanoGenizer microjet nanohomogenizer;

from experiment to large-scale production, the split-valve high-pressure homogenizer has doubled the homogenization valve. Although the flow rate becomes larger, the amplification of the valve body impact ring and valve seat structure is substantially different from the original small homogenization valve during the sample processing process. Although the flow rate increases, the results cannot be repeated; The microjet nanohomogenizer uses parallel replication of diamond microchannels in the diamond interactive chamber and the use of multi-channel diamond interactive chambers to ensure that the flow rate is amplified while the processing effect is consistent with that of the experimental test. In summary, there are many reasons why many original high-end preparations abroad use microjet nanohomogenizers for processing.

Only after comparison will I know if it is easy to use, thank you for your approval; of course, there is still a lot of room for optimization. Stay hungry, stay foolish. Suzhou Microflow Association continues to grow and improve.

For more materials, please refer to:

1. Brief introduction to working principle and characteristics of microjet high-pressure homogenizer。

2. Genizer Microjet Diamond Interactive Cavity User Guide.

| manager Wang Tel: 13020218906 Email: biotech@willnano.com Website: www.willnano.com Suzhou Microfluidic Nanobiotechnology Co., Ltd. |

苏州微流纳米Vic