苏州微流纳米生物技术有限公司

What is dynamic high-pressure microjet? Why is the dynamic high-pressure micro-jet homogenizer more effective than the traditional high-pressure homogenizer? Dynamic high-pressure microjet technology (dynamic high pressure microfluidization (DHPM) is an advanced high-pressure processing technology. It is based on high pressure theory, fluid mechanics theory, and impinging stream theory. It integrates multiple unit operations such as transportation, mixing, micro-crushing, pressurization, and expansion. It can perform a series of comprehensive effects such as strong shearing, high-speed impact, instantaneous pressure release, high-frequency oscillation, expansion and cavitation on fluid mixed materials, thereby achieving good miniaturization, Microemulsification and homogenization effect. Dynamic high-pressure technology represents an important innovation because it can be used to modify emulsions or biopolymers and can be used in industrial production.

Application principle of dynamic high-pressure microjet technology

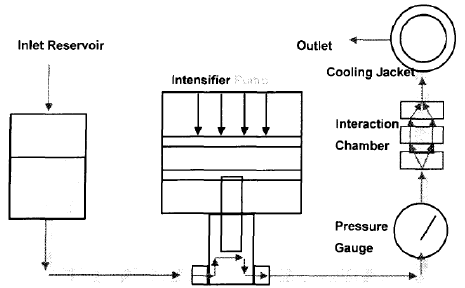

Dynamic high-pressure microjet is a special form of high-pressure homogenization technology. Dynamic high-pressure microjet homogenizer is developed on the basis of dynamic high-pressure microjet technology, with the main purpose of realizing emulsification and homogenization of materials. A technical equipment. The dynamic high-pressure microjet homogenizer is mainly composed of a hydraulic pump and an impact chamber. It uses the high pressure generated by the hydraulic pump to disperse the fluid in the impact chamber into two or more streams, and perform a strong high-speed impact in an extremely small space. Most of its energy is instantly transformed during the impact process, creating a huge pressure drop, which makes the liquid particles highly fragmented. It is a brand-new technology that integrates multiple unit operations such as transportation, mixing, micro-crushing, pressurizing, heating, and puffing. It is mainly suitable for shearing, crushing, homogenization and expansion of liquid-liquid phase or liquid-solid phase of fluid mixed materials. In this homogenization process, severe processing conditions such as high-speed liquid impact, high shear, hole explosion, high-speed oscillation, etc. may cause changes in the macromolecular structure, thereby causing changes in the physical properties of the material.【1】

Figure 1.& nbsp; Schematic diagram of working principle of dynamic high-pressure microjet homogenizer

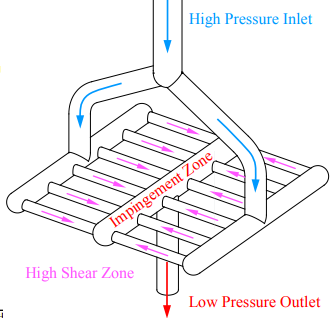

In microjet homogenizers, in order to achieve the effect of jet collision, the main mechanical form is the use of high-speed liquid streams to spray onto solid materials (liquid-solid collision) and collision between high-speed fluids (liquid-liquid collision). Therefore, the design of the impingement chamber is the core element that determines the effect of the dynamic high-pressure microjet homogenizer.

Figure 2.& nbsp; Structural diagram of the core reaction chamber of dynamic high-pressure microjet technology [2]

Dynamic high-pressure microjet homogenizer

Dynamic high-pressure microjet technology integrates high-pressure jet technology, impinging stream technology and traditional high-pressure homogenization technology, and has a more efficient, stable and safe nano-scale material processing effect.

A series of high-pressure microjet homogenizers manufactured by Genizer Company of the United States using dynamic high-pressure technology have a greatly improved pressure compared with traditional high-pressure homogenizers. The application of microjet technology makes it very different in working principles from traditional valve-type high-pressure homogenizers. During the treatment process, the material is pressed for a very short time (less than 0.001s), and the pressure change rate is large, and the pressure can rise to 300MPa. At the same time, two or more microjets in the bullet type (speed can reach 500m/s) pass through the high shear of the diamond cavity in the homogeneous cavity, and then collide with each other after being separated in the diamond Y-shaped channel. During the process, the material is subjected to effects such as collision explosion, high-frequency shear oscillation, cavitation, pressure drop, etc., so that the material achieves nanoscale uniform refinement.【3】

Suzhou Microfluidic Nano is the general supplier of Genizer in Asia. The Genizer microjet high-pressure homogenization and liposome extrusion equipment it supplies can be used for nano new materials, nano emulsions, liposomes, suspensions, new energy dispersions, etc. Material processing process is used to achieve functions such as nanoscale particle size, narrow distribution, uniform mixing, stable suspension, loose mass dispersion and graphene stripping. It mainly serves nano new materials, medicine, biotechnology, cosmetics, high-end drinks and other industries. The Suzhou Microfluidic Nanotechnology team has rich service experience in the field of microfluidic homogenization, fully grasps the structural technology of the equipment, and provides customers with solid services such as installation, training, maintenance, and repair of microfluidic high-pressure homogenization equipment. It has won awards such as Tsinghua University, University of Science and Technology Beijing, Nanjing University, Zhejiang University, Sichuan University, Anhui Medical University, China Pharmaceutical University, Shandong University, Wuhan University, Huazhong University of Science and Technology, Xi'an Jiaotong University, Cooperation has been recognized by more and more scientific and technological cutting-edge units such as the Lanzhou Institute of Chemical Physics of the Chinese Academy of Sciences, the Institute of Chemical Defense of the Academy of Military Sciences of the People's Liberation Army, and the China Academy of Engineering Physics.

For more information on thecharacteristics of the microjet diamond interactive chamber and the microjet high-pressure homogenizer and the comparison with traditional high-pressure homogenizer, please see Annex 3 for details.【3】

【1】Studying the effects of adsorption recoalescence and fragmentation in a high pressure homogenizer using a dynamic simulation model_Andreas.pdf

【2】Y-TYPE Diamond Interaction Chamber for High Pressure Homogenizer.pdf

【3】Introduction to the working principle and characteristics of microjet high-pressure homogenizer

[4] Genizer microjet diamond interactive chamber use guide.

more details, please contact

| manager Wang Tel: 13020218906 Email: biotech@willnano.com Website: www.willnano.com Suzhou Microfluidic Nanobiotechnology Co., Ltd. |

微流纳米王